Quick Reference Chart

| Technology Type | All PolyJet | VisiJet Clear (MultiJet) | Polylactic Acid (FFF) | Onyx (FFF) | High Temp (SLA) | Nylon 12 (SLS) |

| Build Volume(mm) | 294 x 192 x 148.6 | 290 x 200 x 140 | 240 x 200 x 200 | 310 x 130 x 150 | 75 x 75 x 150 | 160 × 160 × 300 |

| Resolution(μm) | 50 | 25 | 200 | 100μm | 100 | 110 |

| Minimum feature size(μm) | 250 | 100 | 300 | 300 | 300 | 250 |

| Unique Properties | Very smooth surfaces. Ideal for mold making and PDMS Casting. | Highest resolution option. Can be made fully transparent by applying oil or clear coat. | Most affordable option. Best for early stage prototyping. | Stiffest material option. Great for mechanical components. | Can withstand temperatures of up to 140 °C without deflecting. | Physically Isotropic. Best option for high strength applications. |

Printer and Material Reference

Selective laser Sintering(SLS): Formlabs Fuse 1 Printer

More machine information | General Info: • Max Build volume: 160 × 160 × 300 mm, 6 x 6 x 11.5 in • Resolution: 110μm • Minimum recommended feature size: 250μm |

Materials:

Nylon

| Pros • Most durable material offering • Nearly completely isotropic • More flexible than other materials • Great for enclosures, fixtures, and mechanical parts • UV Resistant | Cons • Lower tolerances than most other materials • Rough surface texture • Lower repeatability than other printing technologies • Internal channels and features do not always succeed • More prone to warping than other materials |

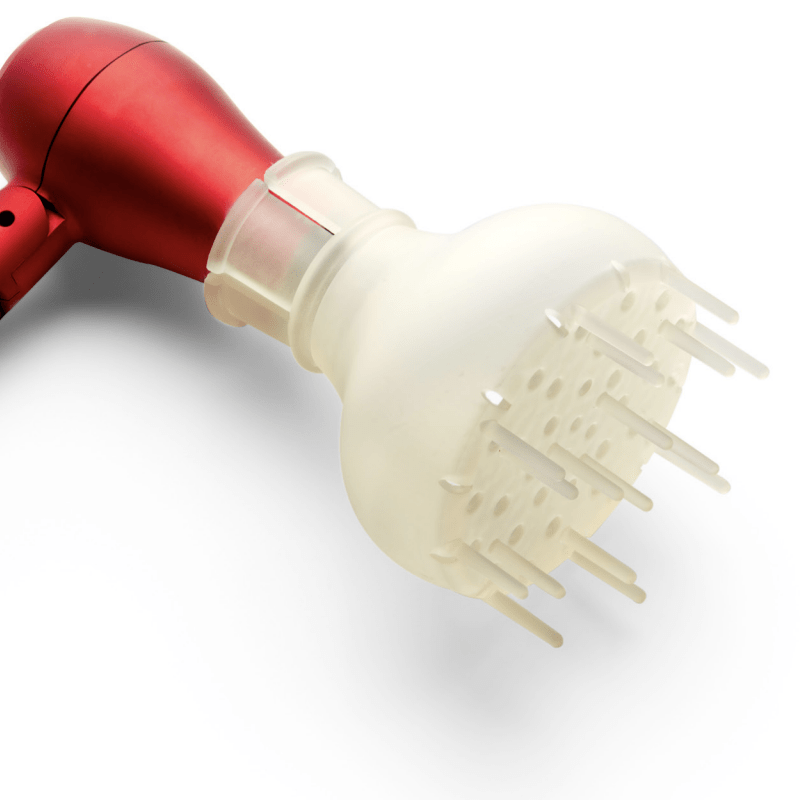

PolyJet: Stratasys J-series Printer

More machine information | General Info: • Max Build volume: 294 x 192 x 148.6 mm, 11 x 7.5 x 5.5 in • Resolution: 50μm • Minimum recommended feature size: 250μm |

Materials:

VeroUltra: White, Cyan, Magenta, Yellow, Clear

| Pros • Has the capability to print in multi-color • Second highest tolerances among available technologies • Completely isotropic and watertight • Great for biomedical and “looks like” prototypes • Clear material can be made biocompatible | Cons • More brittle than PLA, Nylon, and Onyx materials • If under pressure, the material will deform over time • Not UV resistant • Will deform under relatively low temperatures |

Elastico

| Pros • Most flexible material offering • Completely isotropic and watertight • Great for biomedical prototypes | Cons • Relatively low tear strength • Material is flexible, but not very elastic • Internal structures may have residual support material |

Digital ABS Plus

| Pros • Completely isotropic and watertight • Higher resolution than most other robust materials • Higher strength and heat resistance | Cons • More expensive than some other stronger materials |

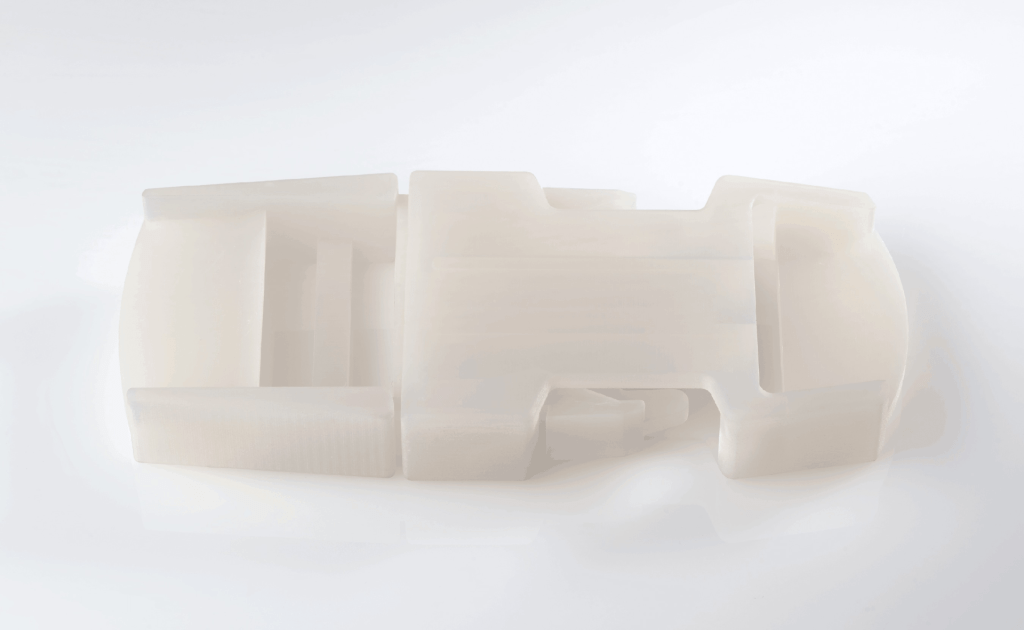

PolyJet: Stratasys Objet30 Printer

More machine information | General Info: • Max Build volume: 294 x 192 x 148.6 mm, 11 x 7.5 x 5.5 in • Resolution: 50μm • Minimum recommended feature size: 250μm |

Materials:

Vero White

| Pros • Relatively high tolerances • Completely isotropic and watertight • Great for PDMS casting | Cons • More brittle than PLA, Nylon, and Onyx materials • If under pressure, the material will deform over time • Not UV resistant • Will deform under relatively low temperatures |

Durus

| Pros • More durable than all other resin materials • Relatively high tolerances • Completely isotropic and watertight | Cons • If under pressure, the material will deform over time • Not UV resistant • Will deform under relatively low temperatures |

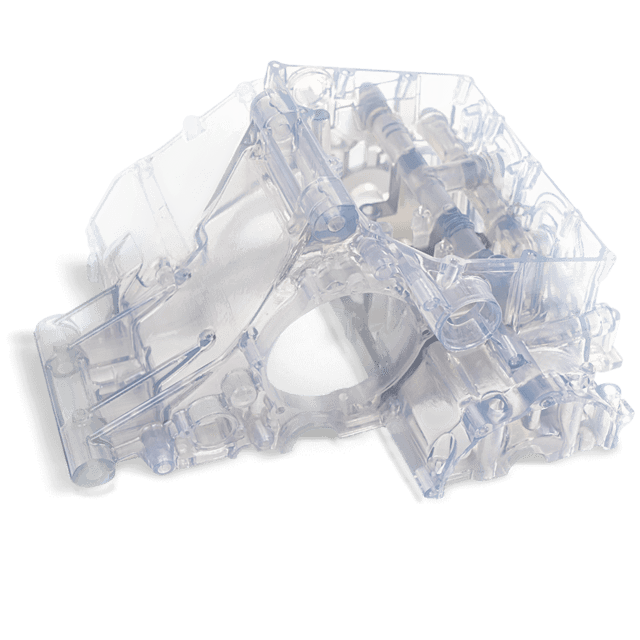

High Definition MultiJet Printing(MJP): MJP 2500 Printer

More machine information | General Info: • Max Build volume: 290 x 200 x 140 mm, 11 x 8 x 5 in • Resolution: 25μm • Minimum recommended feature size: 100μm |

Materials:

VisiJet Clear

| Pros • Highest tolerance material • Completely isotropic and watertight • Great for microfluidics • Great for internal cavities | Cons • More brittle than PLA, Nylon, and Onyx materials • If under pressure, the material will deform over time • Not UV resistant • Will deform under relatively low temperatures |

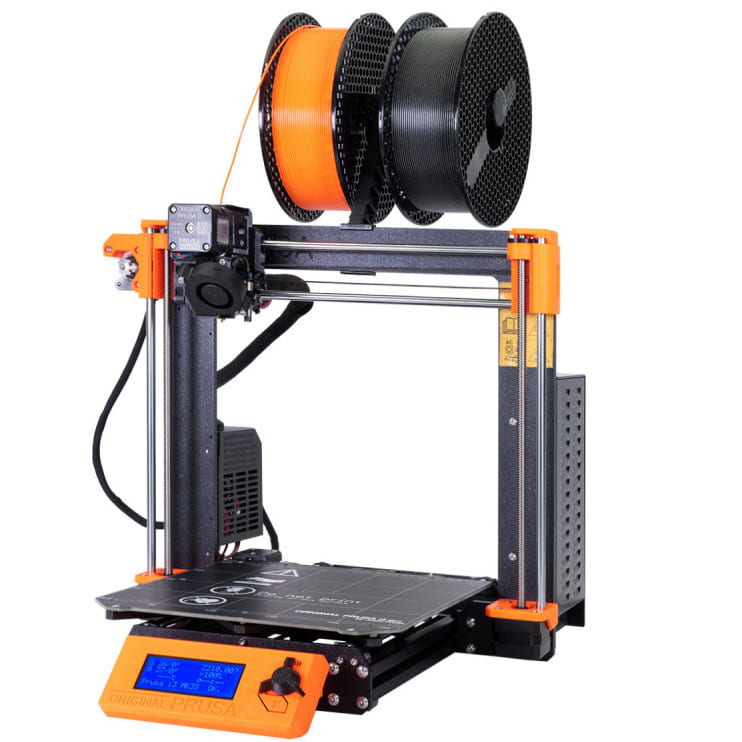

Fused Filament Fabrication(FFF): Prusa I3 MK3S

More machine information | General Info: • Max Build volume: 240 x 200 x 200 mm 9.5 x 8 x 8 in • Resolution: 200μm • Minimum recommended feature size: 300μm |

Materials:

Polylactic Acid (PLA)

| Pros • Lowest cost material • Stronger than most resin options • Great for general prototyping • UV resistant • Best for beginners | Cons • Low strength along layer lines • Lowest resolution • Not isotropic or watertight • Support material may be more difficult to remove • More complicated geometries may be impossible • Fails catastrophically |

Fused Filament Fabrication(FFF): Markforged Onyx One

More machine information | General Info: • Max Build volume: 310 x 130 x 150 mm, 12 x 5 x 6 in • Resolution: 100μm • Minimum recommended feature size: 300μm |

Materials:

Onyx

| Pros • Stronger than all resin options • Great for general prototyping • Great for wearables • Does not fail catastrophically • UV resistant | Cons • Low strength along layer lines • Not isotropic or watertight • Support material may be more difficult to remove • Internal geometries may be impossible |

Stereolithography(SLA): Formlabs Form 3

More machine information | General Info: • Max Build volume: 75 x 75 x 150 mm, 3 x 3 x 6 in • Resolution: 100μm • Minimum recommended feature size: 300μm |

Materials:

High Temp Resin

| Pros • Can withstand temperatures up to 100 °C • Isotopic(water and air tight) | Cons • Support material leaves marred surface • Worse tolerances than other resin printing options • Worse repeatability than other resin printing options • Internal geometries may be impossible |